Snap vs. Throttle Pilots

Posted by Tori Valigura on Nov 22nd 2019

What are the differences in Snap and Throttle Pilots?

One of the many options to consider when selecting a liquid level controller for your application is the type of pilot that will work best. To make the best decision, it is important to understand how different pilots operate and what makes them different.

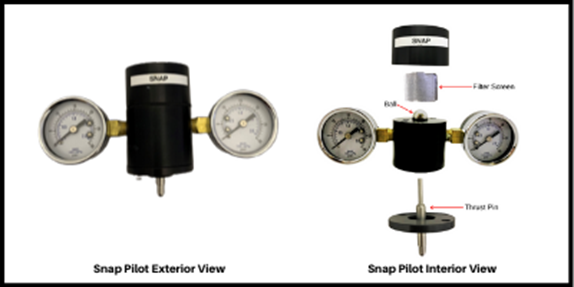

Snap Pilots

When should I use a Snap Pilot?

Snap pilots are referred to as quick

opening due to the way that it puts pressure at 100 percent to the dump valve

once the mechanical force is applied to the push rod. This type of pilot is

used to control interface when there is a large span and space between water

and oil outlets are limited. Snap pilots are a good option for slugging wells

and are typically used in dump applications. They also allow for the most

accurate readings on turbine meters.

Snap pilots are referred to as quick

opening due to the way that it puts pressure at 100 percent to the dump valve

once the mechanical force is applied to the push rod. This type of pilot is

used to control interface when there is a large span and space between water

and oil outlets are limited. Snap pilots are a good option for slugging wells

and are typically used in dump applications. They also allow for the most

accurate readings on turbine meters.

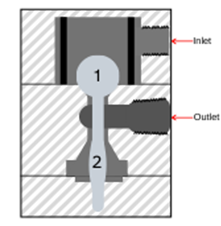

How do Snap Pilots Work?

Snap pilots operate with one valve that controls the flow of gas admitted to the outlet port and another that exhausts pressure. Valve “1” is held closed by the pressure of the inlet airflow. When the force transmitted to thrust pin “2” is strong enough to overcome the force holding Ball “1” seated, “1” snaps upward allowing gas to flow past “1” and out the side port of the pilot.

When the liquid level reaches the desired setpoint, the pin thrusts upwards, opening valve “1” and allowing air to flow through the outlet port. This pressure closes the exhaust valve “2”.Once the liquid level begins to lower the displacer will cause the pin to drop, closing valve “1”. Valve “2” will then open exhausting any pressure remaining.

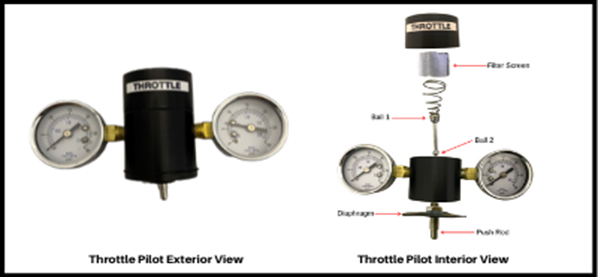

Throttle Pilot

- When should I use a Throttle Pilot?

A pilot is considered a “throttle” pilot when

its output pressure is proportional to the mechanical force applied  to the thrust pin. Throttle pilots maintain a more consistent level and a smaller span

than snap pilots, allowing a larger fluid section to dump in a specific period.

Throttle pilots also shorten valve travel, increasing the life of a valve.

to the thrust pin. Throttle pilots maintain a more consistent level and a smaller span

than snap pilots, allowing a larger fluid section to dump in a specific period.

Throttle pilots also shorten valve travel, increasing the life of a valve.

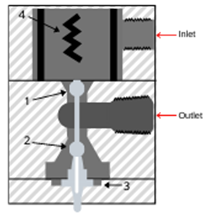

- How does a Throttle Pilot Work?

A throttle pilot works differently from a snap by using a diaphragm “3” and a spring “4” in conjunction with valves “1” and “2” to create a force balanced throttling pilot. When the liquid level rises, the pressure of the rising displacer will force the pin upwards and open valve “1” allowing the inlet pressure to flow through the outlet port. This outlet pressure also pushes back on diaphragm “3” with the same force applied. Valve “1” will either open or close as the pressure changed on the pin, allowing forces to become balanced once again. If valve “1” closes, valve “2” will open and exhaust the pressure.

If your application changes and requires you to switch from a level controller with a snap pilot to a throttle pilot or vice versa, the pilot can be swapped out without replacing the level controller. Some level controllers have reversible field action, meaning the pilot can switch back and forth from snap to throttle mode, eliminating the need to replace the pilot if the opposite mode becomes necessary.

For more tips on how to select the best level controller options for your application, click here.

Want to look at all parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified separators? Click here for Croft Production Systems