What is a Liquid Level Gauge?

Posted by Tori Valigura on Feb 27th 2020

What is a Liquid Level Gauge?

A liquid level gauge, also known as a level indicator or sight glass, is a meter that is used to determine liquid level in a process tank, vessel or drum. A level gauge is simply a glass tube that gives a visual representation of the level of liquid that is in the vessel. While simple in their design, they are a very effective technology for a direct visual indication of process fluid level. There are many applications across the industry that require the monitoring of the liquid level and there are many different types of level indicators to fulfill these varying needs. In many situations the fluid is dangerous or the place in which the liquid is stored is of such a nature that it is manually impossible to find the level, making some sort of level indicator imperative.

Types of Liquid Level Gauges & Level Indicators

Gauge Glass

Plain glass tube level gauges, also known as sight glass or gauge glass, are tubular glass gauges that are not encased in metal plates. These tubular gauges come in a clear color or with a red line, which improves the visibility of clear liquids. Tubular gauges come in many different diameters and lengths, which are often custom cut to the client’s specifications. Finishes on the ends of tubular glass gauges are seen cut, ground, or polished depending on client specifications. Tubular Glass Gauges are often used in low-pressure applications up to 600 psi.

Transparent Level Gauges

Transparent gauges contain the liquid medium between two pieces of glass on opposing sides of the chamber. Light shines through one side of the gauge, and the level is viewed from the other side. The fluid level is indicated as the result of the different transparency of the two media. Transparent Level Gauges can be purchased with tubular glass or flat glass. While tubular glass is more cost-effective, flat glass designs can better withstand applications with high pressures.

Transparent gauges are a good choice in applications where the actual liquid characteristics need to be seen, as well as with liquid to liquid interfaces and applications with repetitive thermal shock. They can also be used when corrosive liquids are present with the addition of mica shields. Mica shields are used when acidic solutions or hot alkaline are present to protect the integrity of the glass.

Reflex Level Gauges

Reflex Level Gauges

Reflex glass level gauges work off light refraction and reflection. The glass has several grooves for reflecting prisms. The liquid level is easily identified with different brightness levels of the glass in the liquid and no illumination is required to view the liquid level.

Reflex Level Gauges allow for a better view of clear liquids because they are equipped with special optics that make the liquid visible. Reflex level indicators are often used in high-temperature applications, specifically for boiling liquids. Boiling liquids levels can be hard to read with other types of level gauges since their bubbles make the surface level questionable. The manual adjustment of the isolation valve as the process fluid enters the chamber reduces the bubbling. Reflex Level Gauges are also suitable in applications with high pressures and corrosive process fluids. Reflex level gauges are not suitable for when the interface between two liquids needs to be read.

Magnetic Level Gauges

A magnetic level gauge, or magnetic level indicators measure fluid levels by utilizing a float that rises and falls with the fluid level. The moving of the magnet assembly adjusts a series of bi-color magnetic flags that provide a visual indication of the liquid level. The mechanics of these level indicators are simple are require no power source yet are very effective and reliable at recording liquid levels. They are also virtually maintenance-free, and the magnetic force can affect optional switches or transmitters mounted outside of the chamber.

Magnetic level gauges are used as security against leakages when process fluids are chemically aggressive, poisonous, inflammable or explosive. Magnetic level indicators can be used in a wide variety of applications and are considered alternative to glass gauges.

What is a Gauge Valve Set?

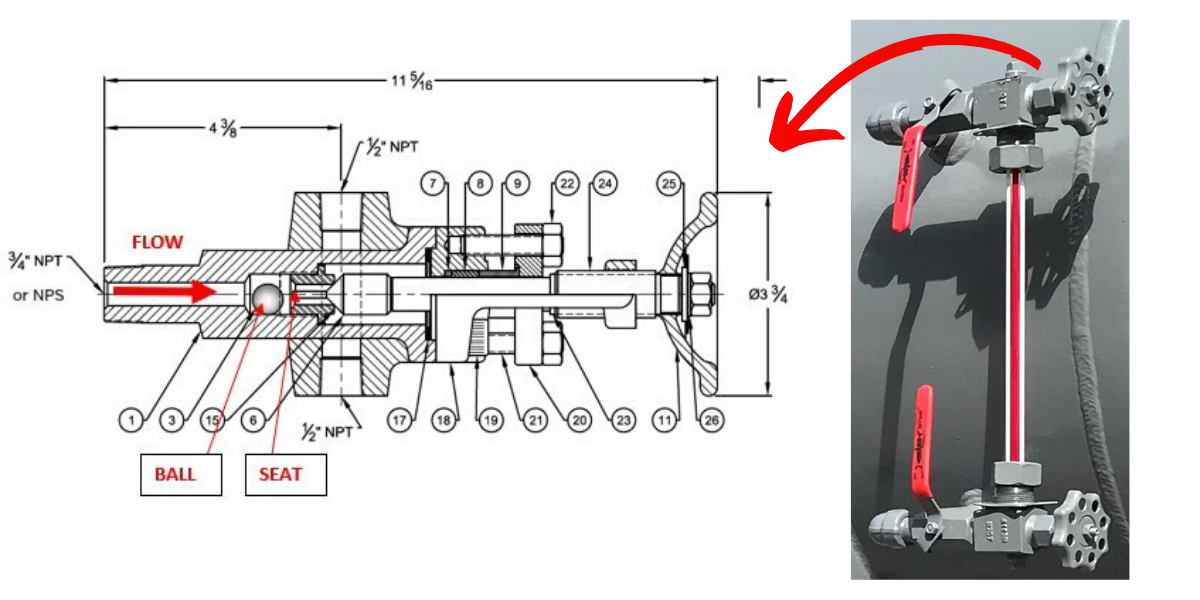

Gauge valve sets, also known as gauge cocks, are valves that are placed on the ends of glass gauges to isolate the gauge chamber from the liquid contents of the vessel. Level gauge valves allow for the replacement of a sight glass or liquid level gauge without disrupting the levels or pressure of the tank or vessel. In the case of a tube rupture, these valves will prevent the escape of the process fluid.

These valves are usually equipped with flow-limiting devices in the event of a tube rupture, so too much process fluid does not escape even when the valves are fully open. In the event of the glass breaking these valve sets have a ball check as fluid begins to steady flow out the ball will be pushed out on to a sealing seat blocking the flow and sealing off fluids from leaking out of the vessel. Slower amounts of fluid flow velocity in normal operations do not check the ball.

Selecting a Level Indicator for Your Application

When selecting a gauge valve set the main thing to look at are the vessel connection ports, NACE requirements, pressure and temperature rating. A good way to determine what you need is by looking at your vessel pressure/temp rating on the plaque or U1A. This information will help you determine what specs you need to meet in your selection.

Croft Supply has sight glasses, liquid level gauges, and gauge valve sets available for purchase online. Don’t see what you are looking for? Request a quote and we will do our best to source a level indicator that fits the needs of your application.

Shop all parts that Croftsupply.com has to offer

Shop used or surplus equipment on SurplusEnergyEquipment.com

Purchase new or re-certified processing equipment with Croft Production Systems