What is a Gas Pressure Regulator?

Posted by Tori Valigura on Jan 3rd 2020

What is a Gas Pressure Regulator?

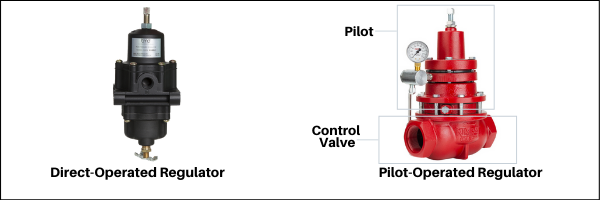

A gas pressure regulator is a control device that maintains a defined pressure of a system by cutting off the flow of a gas or liquid when it reaches a set pressure. Pressure regulators come in several types and configurations and they provide control in a variety of applications in oil and gas processing. All pressure regulators fall under two main categories; direct-operated or pilot-operated.

What are the Differences in a Direct-Operated and a Pilot-Operated Regulator?

A direct-operated regulator, also referred to as a self-operated regulator, is the simplest type of regulator. On a direct-operated regulator, the adjustments are done on the regulator itself rather than on a connected pilot. The essential components that make up a direct-operated regulator are a plug and seat, a diaphragm, and a spring. These regulators respond directly to outlet pressure changes and the flow is adjusted to the pressure set point. The downstream pressure counters the force of the spring, which determines the plug position. The position of the plug in a direct-operated regulator is immediately affected by any change in the outlet pressure.

A pilot-operated regulator, or control valve, has a similar design and the same components as a direct-operated regulator, with the addition of an attached pilot. A pilot-operated regulator is more responsive to changes in conditions. The other difference in the design of a pilot-operated regulator is an external sense line. This sense line is connected to the piping further downstream, which allows for a more accurate reading of the outlet pressure. Overall, the pilot enables the regulator to provide more efficient control of the pressure. Pilot-operated regulators are preferable in applications that have a high flow rate.

What is a Back Pressure Regulator?

Back-pressure regulators are an integrated control

valve, which means that the body of the valve and the pilot are one piece. The

purpose of a back pressure regulator is to monitor and maintain upstream pressure

by adjusting the set point to the desired maximum upstream pressure. Once that

previously determined set point is reached, pressure is then released

downstream.

Back-pressure regulators are an integrated control

valve, which means that the body of the valve and the pilot are one piece. The

purpose of a back pressure regulator is to monitor and maintain upstream pressure

by adjusting the set point to the desired maximum upstream pressure. Once that

previously determined set point is reached, pressure is then released

downstream.

Back pressure regulators operate using a bolt mechanism that adjusts the tension of the spring. The flow triggers the sensing diaphragm to apply pressure to the spring, which positions the pilot plug to allow the upstream gas to push the diaphragm down. The flow underneath the plunger is simultaneously pushing the plunger up, keeping the valve in a closed position until the pressure exceeds the set point. Once this occurs, the valve opens and allows the gas to vent from the top of the diaphragm. Once the back pressure on the inlet side is reduced, the valve reverts to its normal, closed position.

Oil and gas producers use back pressure regulators to maintain pressure on production equipment such as separators, heater treaters, free water knockouts. They are also used for gas line sales, flare lines, and any other application where holding back pressure is necessary.

Back pressure regulators are also referred to as back pressure valves, pressure sustaining valves, or pressure sustaining regulators. They operate similarly to a pressure relief valve (also known as a pop-off, PSV, or Pressure Safety Valve) as both control the pressure upstream of the valve. The difference between a backpressure regulator and a pressure relief valve is that the regulator maintains a consistent flow control, while a pressure relief valves serve as a safety device that opens only if the pressure reaches the predetermined set point.

What is a Pressure Reducing Regulator?

A pressure reducing regulator works the

opposite of a back pressure regulator in that it monitors and controls the

pressure downstream of the valve. The purpose of a pressure reducing regulator

is to reduce the inlet pressure to the desired outlet pressure.

A pressure reducing regulator works the

opposite of a back pressure regulator in that it monitors and controls the

pressure downstream of the valve. The purpose of a pressure reducing regulator

is to reduce the inlet pressure to the desired outlet pressure.

Just as a back pressure regulator, reducing regulators operate using a bolt mechanism that adjusts the tension of the spring. The flow triggers the sensing diaphragm to apply pressure to the spring, which positions the pilot plug to allow the upstream gas to flow under the diaphragm. The flow underneath the plunger is simultaneously pushing the plunger up, keeping the valve in an open position until the pressure exceeds the set point. Once this occurs, the valve closes and forces the gas to vent from underneath the motor valve. Once the pressure is reduced below the setpoint, the valve reverts to its normal, open position.

Oil and Gas Producers use Pressure Reducing Regulators in applications such as suction controllers on a natural gas compressor or recirculation valves on natural gas compressors. They are also used on gas meter runs or to supply fuel or instrument gas on production equipment and any other application requiring a reduction in pressure to regulate downstream.

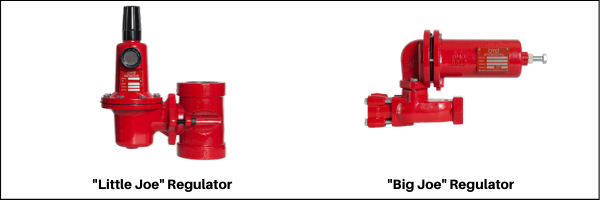

Pressure reducing regulators are also referred to as a pressure control valve or pressure reducer valve. When referencing a high pressure or low pressure regulator, many use the phrase “Big Joe Regulator” or “Little Joe Regulator” respectively to clarify which type of pressure reducing regulator it is that they need.

What are Big Joe and Little Joe Regulators?

The terms “Big Joe” and “Little Joe” originally referenced a specific Fisher® line of pressure reducing regulators, but since has evolved into common terminology used across the industry to describe a high pressure regulator (Big Joe) or a low pressure regulator (Little Joe).

Big joe regulators and little joe regulators

are direct spring operated, pressure reducing regulators. A big joe regulator

handles outlet pressures up to 500 psig, while a little joe regulator handles

outlet pressures up to 150 psig.

What Factors Should I Consider When Selecting a Regulator?

As with most parts for your gas processing equipment, there are several factors to keep in mind when selecting the best regulator for your operation. Some of those factors are your upstream pressure, your desired downstream pressure, temperature range, and fluid type.

- Pressure-Your upstream pressure (inlet pressure) and downstream pressure (outlet pressure) are both important to keep in mind when selecting your regulator. Your outlet pressure will help you establish your requirements for the springs, casing pressure rating, body outlet rating, orifice rating and size, and the size of the regulator itself. Your inlet pressure determines your requirements for the body inlet pressure rating, orifice pressure rating and size, and the regulator size. Depending on your pressure differential, or the difference in your inlet pressure and the desired outlet pressure, it may be necessary to have both a high pressure regulator and a low pressure regulator in order to obtain the pressure drop that is necessary to reach the desired outlet pressure. This can be achieved by using both a low pressure and high pressure, single-stage regulator or using one dual-stage regulator.

- Temperature- While not nearly as important as your pressure range, the temperature range of your application can play a factor in selecting the best regulator option for your operation. For example, higher temperature may require you to select a regulator with stainless steel material. Before you purchase a regulator, make sure to take look at the technical data sheet, or spec sheet to be sure that the regulator you are selecting is compatible with the temperature range of your application.

- Fluid Type: Finally, the fluid should be taken into consideration when selecting a regulator. Whether your application is liquid, gas, or steam, will affect the formula for properly sizing your regulator. It is also important to keep in mind the chemical composition of the process fluid to be sure that the materials are adequate for handling the fluid. The Diaphragm and seat materials should be select to be compatible to handle the process medium flowing through the regulator. Make sure to reference the data sheets to confirm that the regulator will work for your specific fluid type.

Other options that you will want to evaluate are; line size, material compatibility, trim material, orifice size, connection type, the stroking speed, the shutoff capability and whether you want direct-operated or pilot-operated.

What Pressure Regulators are available on Croft Supply?

Croft Supply has the following pressure regulators available for purchase.

- Kimray Back Pressure Regulator (Or Valve)

- BMD RG10 “Big Joe” Pressure Regulator

- BMD RG20 “Little Joe” Pressure Regulator

- BMD RG30 Pressure Regulator

- BMD RG40 Pressure Regulator

Don't see what you are looking for? Please contact us and let us know. We will do our best to get the regulator that fits the needs of your operation.

Want to look at all parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified processing equipment? Click here for Croft Production Systems.