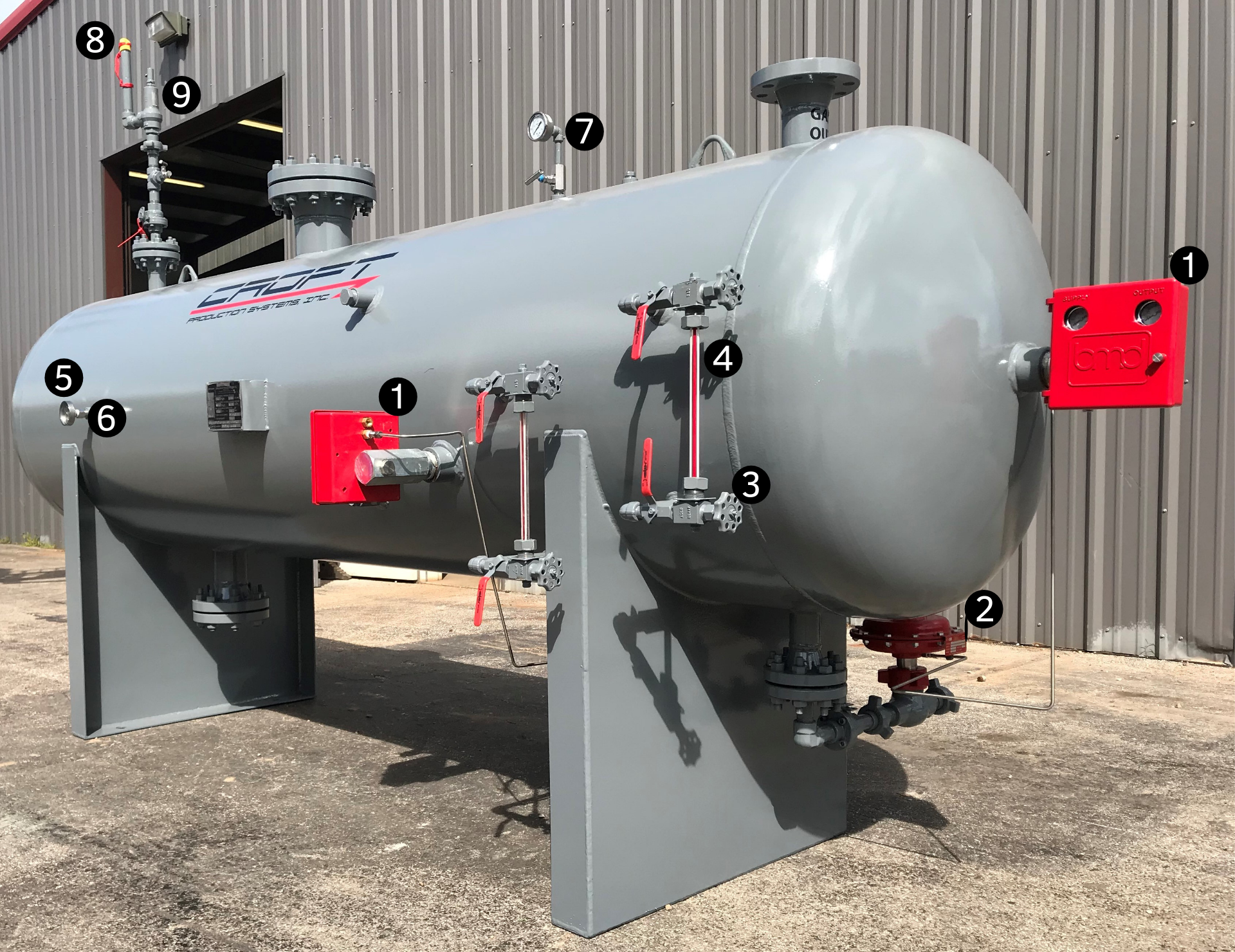

Parts of a Horizontal Separator

Posted by Cameron Croft on Jan 3rd 2023

What is a horizontal separator?

A horizontal separator is a vessel for the bulk removal of liquids or solids by gravity. Operators prefer to utilize a horizontal separator over other separators when the well streams have large liquid-to-gas ratios, constant flow, and small liquid surge characteristics (high liquid/ gas). Other reasons could be when work areas have vertical height limitations; horizontal separators are smaller and less expensive than vertical separators for a given gas capacity. Horizontal separators are also preferred with well streams experiencing foamy production or well streams requiring three-phase separation applications with more efficient liquid-liquid separation. These separators may go by many names, like horizontal separators, oil-water separators, knockouts, and scrubbers, but the primary function of separation is the same. For these reasons, it is essential to have appropriately functioning parts because it is just a pressure vessel without them.

What parts go to a horizontal separator?

CROFT Supply.com focuses on parts used for separators dedicating an equipment category for all parts used for separators. Below you will find a brief description of the separator parts available on Croft Supply:

1. Liquid Level Controllers - Liquid level controllers maintain the desired level in a vessel. The displacer floats in the process fluid and as the fluid level passes to the high-level set point. The liquid level controller pilot sends signals to the dump valve to open. As the level decreases and reaches the low-level set point, the pilot stops sending supply gas to the dump.

2. Dump Valves- A dump valve is opened by the controller to drain the liquids from a vessel.

3. Gauge Valve Sets - These valves isolate process fluid when replacing a broken sight glass.

4. Sight Glass- A sight glass is a transparent glass tube that lets you see the fluid process level inside a vessel.

5. Temperature Gauges - Temperature gauges are designed to show process temperature.

6. Thermowell - Thermowells are designed to block the process fluid and to be a connection port for temperature gauges.

7. Pressure Gauges - Pressure Gauges are designed to show process pressure.

8. Vent Caps - Vent caps protect the PSV from rainwater. This vent cap also has a whistle vent integrated for low amounts of pressure-relieving that is usually not noticeable.

9. Pressure Safety Valves -The pressure safety valve will open if the process pressure exceeds the factory set pressure. The PSV ensures the safety of the equipment.

What parts will I need to replace on my separator?

Some parts will last years without issue, but moving parts may need replacement depending on the unit's service and the components' usage.

Level controllers are typically long-lasting but can have trouble with the pilot after as little as six months if they have an inadequate gas supply. Gas can start leaking through the pilot when it is not operating, or excessive gas can escape when it is actuating. If your level controller is hissing loudly when it is trying to dump, then the seals in the pilot are probably wearing out. Typically, you can replace the pilot, but it is sometimes easiest to replace the entire level controller.

Dump valves will wear out quicker the more they operate but are most susceptible to bad supply gas that wears out the actuator or solids in the dumped liquids that can wear out the trim. Minimally you should check them every six months to see that they are operating smoothly when activated and when shut, they are not allowing pressure to bleed off downstream.

Sight Glasses should be cleaned to ensure they can be read accurately, but they will typically last for years. The sight glass valves should be able to seal the glass section off for cleaning and should be replaced if they cannot, especially if there are no block valves between the sight glass valves and the vessel.

Gauges typically last years but can start to drift over time, especially if they cycle frequently. While some temperature gauges can be reset if they have an adjustment screw, it is typically better to replace pressure gauges if they are reading incorrectly or have discolored to the point they cannot be read easily. Remember to consider the material of the gauges if you have H2S in the gas, brass gauges are cheaper, but the H2S will severely corrode brass.

Pressure Safety Valves (PSVs) can last years and still accurately relieve at their set value but should be regularly checked with a Pop test to ensure that they will work or be replaced on a schedule. As they get older, their pop pressure can drift, or the seat can wear out and not reset properly, leaking gas. PSV caps should always be used to prevent corrosion inside the PSV, but they are also a great indicator that they have popped or are leaking.

Want to look at all the separator parts Croftsupply.com has to offer? Click here.

Want to look at all the separator parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified separators? Click here for Croft Production Systems.