What is a Pressure Safety Valve?

Posted by Tori Valigura on Jan 22nd 2020

What is a Pressure Safety Valve? (PSV)

A Pressure Safety Valve, also referred to as a pop-off valve, is a type of Pressure Relieving Device (PRD) that is used to release gases or liquids, and thus relieve pressure, in the case that the pressure in a vessel reaches a pre-determined setpoint. The purpose of a safety valve is to be the last line of defense in protecting equipment, the environment, and most importantly personnel. Unlike a pressure regulator, a pressure safety valve should be used as a final measure to prevent accidents, rather than consistently maintaining pressure. Because of this, pressure safety valves are heavily regulated and must meet ASME Code requirements.

Because of the importance of a PSV, the valve must be able to operate at any time in any condition. The operation of a pressure safety valve cannot rely on a power source so that it is operable in the case of a power outage. Therefore, all pressure safety valves ultimately rely on the process fluid to open and close the valve. The specifics on the valve operation are different depending on if the PSV is spring-loaded or pilot operated.

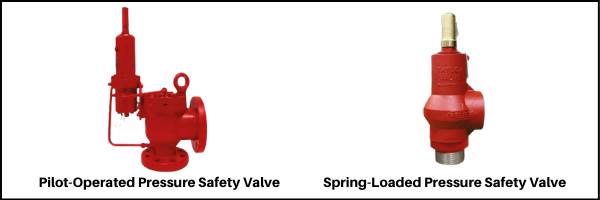

What are the differences in the operation of a spring-loaded and pilot-operated pressure safety valve?

In a spring-loaded PSV, also referred to as direct operating, the valve is closed by the force of the spring, which is compressed by an adjusting screw. This applies pressure to the spindle which keeps the disc sealed against the nozzle seat. As long as the spring force is greater than the force being applied by the process fluid, the valve will remain closed.

In an overpressure event, the force of the process fluid will overcome the spring force and the disc will no longer be sealed to the seat. When the setpoint pressure is just met, the valve will be being to leak. The link may be heard before it is seen. As pressure continues to increase above the setpoint, the valve will suddenly pop off (hence the name pop-off valve) and alleviate the pressure of the vessel.

Spring-operated regulators are more suitable for applications with high-pressure set points and corrosive process fluid than a pilot-operated PSV. Spring-operated valves are sensitive to back pressure and work best in applications where back pressure is not present.

A pilot-operated pressure safety valve has a similar design and the same components as a spring-operated pressure safety valve, with the addition of the attached pilot. Unlike the direct-operated, a pilot-operated PSV relies on the pilot to signal the main valve to open and close. In normal conditions, the pressure is picked up at the main valve inlet and is sent to a dome above the main valve. This inlet pressure applies enough force to the dome to keep the main valve seat closed. Once the set pressure is reached the pilot is actuated, the pilot will open to relieve the overpressure.

Pilot-operated safety valves are recommended for applications with fluctuating or high amounts of back pressure because of the ability to vent of pressure and prevent cycling. Pilot-operated is also a good option for equipment that requires a low accumulation rate as the pilot allows for operation close to the set point without any leakage.

What is the difference in a Pressure Safety Valve (PSV) and a Pressure Relief Valve (PRV)?

The terms Pressure Safety Valves (PSV) and Pressure Relief Valves (PRV) are often used interchangeably throughout the industry depending on company standards. Although PSVs and PRVs ultimately serve the same purpose, there are some differences in how they operate, the capacity, and the setpoint.

A pressure relief valve, which is typically set at 10% above the maximum operating pressure, opens proportionally to the pressure increase. A pressure safety valve, which is typically set at 3% above the maximum operating pressure, fully opens as an almost-immediate response to overpressure. A pressure relief valve is also usually controlled by an operator, while a pressure safety valve opens automatically without being prompted by an operator.

Pressure Safety Valves and Pressure Relief Valves are both referred to as Safety Relief Valves in some circumstances. In technical terms, a Safety Relief Valve has characteristics of both a PSV and PRV and can be used in either application.

While PSVs, PRVs, and Safety Relief Valves are referenced differently and interchangeably throughout the industry, it is important to understand the differences in the technical terminology so that you can be sure that the valves purchased operate in a way that is safe and efficient for your application.

What causes an over-pressurized vessel?

An overpressure event is defined as any condition that could cause the pressure of a vessel to exceed the maximum working pressure. There are several factors and scenarios that can result in over-pressure in a vessel including, but not limited to, blockage outlets, a cooling system failure, thermal expansions, external fires or heat, chemical reactions, or a valve malfunction.

The above events can all lead to overpressure, either individually or as simultaneous occurrences. Because there are so many variables that can play a factor in causing a potentially dangerous situation, carefully selecting a pressure safety pressure valve is extremely important.

What Factors Should I Consider When Selecting a Pressure Safety Valve?

Because Pressure Safety Valve play such a vital role in the protection of equipment and the safety of personnel, it is imperative to select the best valve for your application. There are several factors that need to be considered before purchasing:

- Set Pressure- You will need to determine the set pressure, which is the pressure point at which your pressure safety valve will need to open.

- Temperature- The temperature affects the volume of the process medium and also determines the what material is required for the valve components.

- Back pressure- The amount of back pressure will determine which type pf pressure safety valve you need.

- Application- Your application and the type of process medium that you are working with (steam, gas, liquid) will also play a factor is selecting a valve with the correct components.

- Connection Size- Safety Valves come in a wide range of connection sizes and types. The valve size needs to be as big as your inlet size and the discharge piping. You will also need to determine your type of connection (ie male vs. female).

- Required Capacity- Determining the maximum capacity is crucial to ensuring the safety of the valve. Pressure safety valves have their limits, so make sure to verify that your PSV can withhold the maximum capacity of your application.

What Pressure Safety Valves are available on Croft Supply?

Croft Supply has pressure safety valve options available from BMD and Taylor Valve. Click here to take a look at what options are available.

Don't see what you are looking for? Contact us with your requirements and we will help you get what you need!

Want to look at all parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified processing equipment? Click here for Croft Production Systems.