What is a chemical injection system?

Posted by Cameron Croft on Aug 5th 2019

What is a chemical injection system?

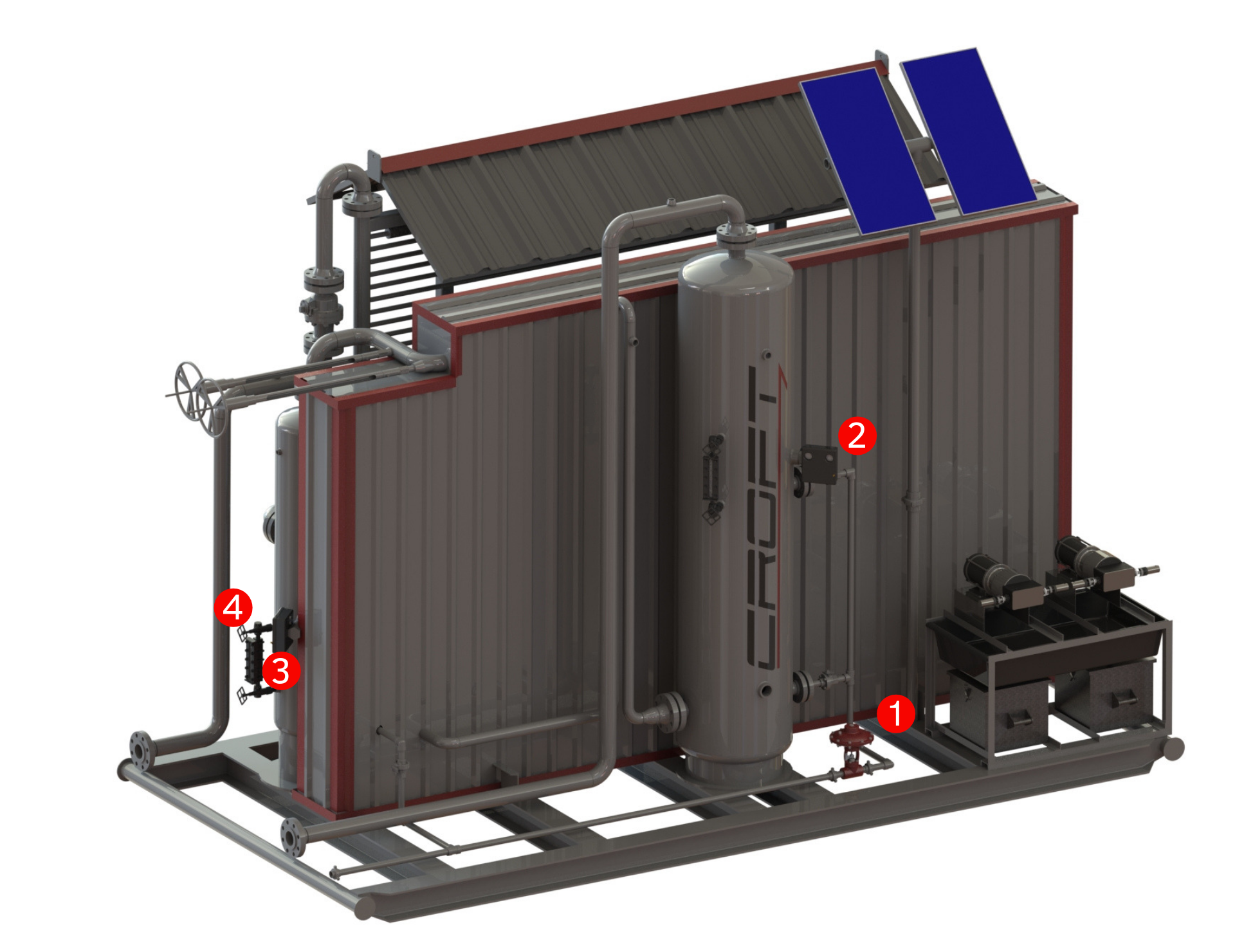

The Chemical Injection System (CIS), is utilized for a wide range of gas processing problems such as the presence of paraffin, hydrates, high salt content, and many other production difficulties. The CIS is an environmentally friendly alternative to an amine plant regarding the removal of H2S. The chemical injection process introduces chemicals to the gas stream that remove impurities or contaminants.

Key parts to a chemical injection system?

Like any mechanical system, a CIS requires regular maintenance, typically on a weekly basis to ensure all parts are functioning accurately. Worn out or faulty componets can compromise the system's effectiveness and overall safelty.

- Dump Valves –Dump Valves keep the system's water and fluids at manageable levels by opening and releasing fluids when specified levels are reached. This prevents overflow and maintianing process stability.

- Liquid Level Controllers – Liquid level controllers detect fluid levels and trigger dumps when level exceed set thresholds. Ensuring automated control of fuild managment.

- Sight Glass – A sight glass is a transparent tube that allows operators to see the process fluid level inside a vessel. Providing a quick check to confirm the system is functioning as expected.

- Gauge Valve Sets –These valves are used when replacing a broken sight glass to isolate process fluid allowing safe maintenance without shutting down the system.

- Pressure Regulators (Not Pictured) – Pressure regulators keep the systems's pressure within safe optimal ranges. They ensure that the chemicals injected are delivered at an acceptable pressure range for effective treatment.

- Pressure Gauges (Not Pictured) – Pressure gauges are designed to show real time process pressure. Assisting operators monitor and adjust the systems preformance as needed.

Thermowells (Not Pictured) – Thermowells are designed to protect temperature sensors from exposure to process fluid and to be a safe connection point for temperature gauges. Ensuring accurate readings without contaminating the proccess.

If you have questions about your CIS or need replacement parts, our team at Croft Supply is here to help.

Want to look at all the CIS parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified chemical injection equipment? Click here.