What is a glycol dehydrator?

Posted by Cameron Croft on Jul 19th 2019

What is a glycol dehydrator?

Natural gas dehydration can be accomplished by a glycol system which removes most of the water content from the gas in order to meet pipeline specs (7 lbs/ MMcf). In colder climates, sales requirements of 3 to 5 lbs/MMcf are common. Another reason for this specification to be met is it prevents water vapor from condensing and creating a corrosion problem within pipelines and equipment. These systems can go by many names likes TEG unit, glycol dehydration plant, glycol system, and many others but the parts on these systems are all relatively the same.

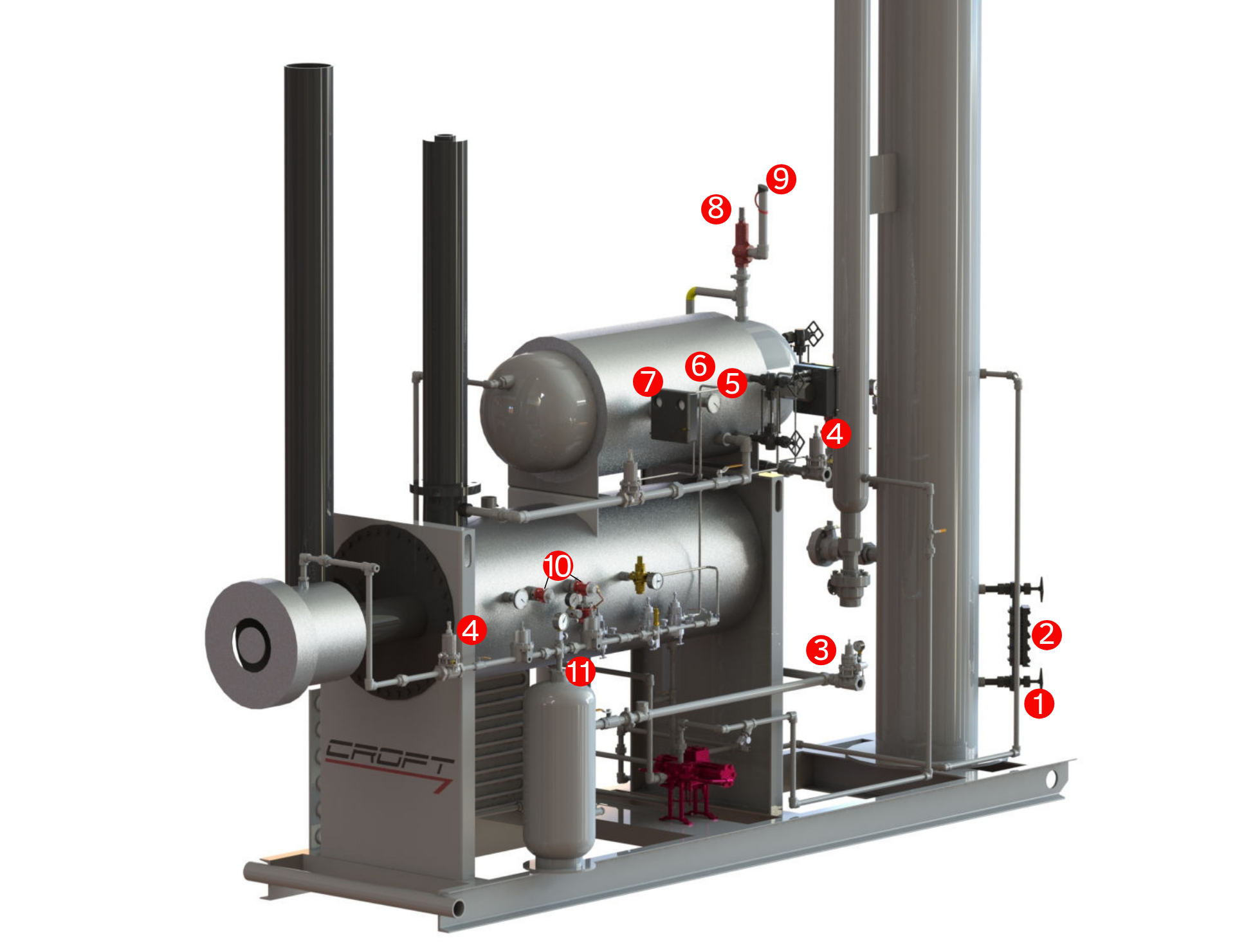

What parts go to a glycol dehydrator?

CROFT Supply.com focuses on parts that are utilized for glycol dehydrators dedicating an equipment category for all parts utilized for glycol dehydration equipment. Below you will find a brief description of the glycol parts:

1.

1.

2. Sight Glass – The sight glass is located on the outside of a glycol dehydrator and allows you to view liquid level.

3 .Back Pressure Valves – Back pressure valves are designed to hold a set pressure on the upstream side.

4. Pressure Regulators – Pressure regulators regulate the pressure to levels that are suitable for instrumentation.

5. Temperature Gauges – Temperature gauges are designed to show process temperature.

6. Thermowells – Thermowells are designed to block the process fluid and to be a connection port for temperature gauges.

7. Dump Valves –A dump valve is opened by a controller to drain the liquids from a vessel.

8. Liquid Level Controllers – Liquid Level Controllers keep the systems water and fluids at manageable levels by triggering dumps to release fluids when they reach specified levels.

9. Pressure Safety Valves – The pressure safety valve will open if process pressure exceeds the factory set pressure. The PSV ensures the safety of the equipment and are also known as PSVs, or pop-offs as well.

10. Vent Caps – The PSV cap is used to protect the PSV from rainwater. This vent cap also has a whistle vent integrated for low amounts of pressure relieving that is usually not noticeable.

11. Thermostats- The T12 is used to control temperatures. If the process temperature goes under the set temperature the thermostat will open supply to a bypass valve until warmer set temperatures are reached.

12. Fuel Shut Off Valves- The FSV is used to eliminate liquid condensates carry over in the fuel pot. Rich Fuel gas flowing through regulators will have liquid condensates collect in the fuel pot. As the fuel pot level rises, the FSV float rises until it plugs the Vessel shut. This is done to prevent any liquid condensates from entering the burner

13. Glycol Filters (not on picture)- The filters that are used in the TEG system help to remove solids and other particulates. The carbon filter is implemented specifically to reduce the foam content in the stream. Some harmful byproducts that the filters are not able to eliminate are the BTEX chemicals.

Want to look at all the glycol dehydrator parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified glycol dehydration equipment? Click here for Croftsystems.net