What is a Joule Thomson Plant (JT)?

Posted by Cameron Croft on Aug 5th 2019

What is a Joule Thomson Plant (JT)?

The Joule Thomson system, or JTS for short, simultaneously reduces the water dewpoint of gas, recovers valuable hydrocarbon liquids and lowers the BTU (British Thermal Unit) of the gas stream to sales contract specifications or levels suited for high-speed engines.

Gas enters the Joule Thomson System and travels through a series of heat exchangers that pre-cool the gas. The gas then passes through the Joule Thomson valve, which is a high-pressure motor valve, taking a pressure drop and cooling further. Liquids accumulate in the cold separator and are then sent to storage tanks. The cold gas then travels back through the heat exchanger and exits the Joule Thomson System.

The system also utilizes liquid level controllers that communicate with the dump valves to relieve the vessel of any fluids or NGLs when they hit a certain level. The level controllers are important because it is vital to keep liquid levels at a manageable level. If the liquid levels get too high, the fluids or NGLs can end up back in the process stream, completely negating the JTS’s work.

The end goal in a JTS is to efficiently separate and capture the valuable natural gas liquids (NGLs) and reduce the temperature of the gas. These NGLs are butane, pentane, hexane, and all other gas heavies that can be separated and sold as their own product. A properly functioning system can safely stabilize hydrocarbon liquids. The gradual temperature and pressure reduction are taken care of by chokes.

For more information on how a JTS works, click here.

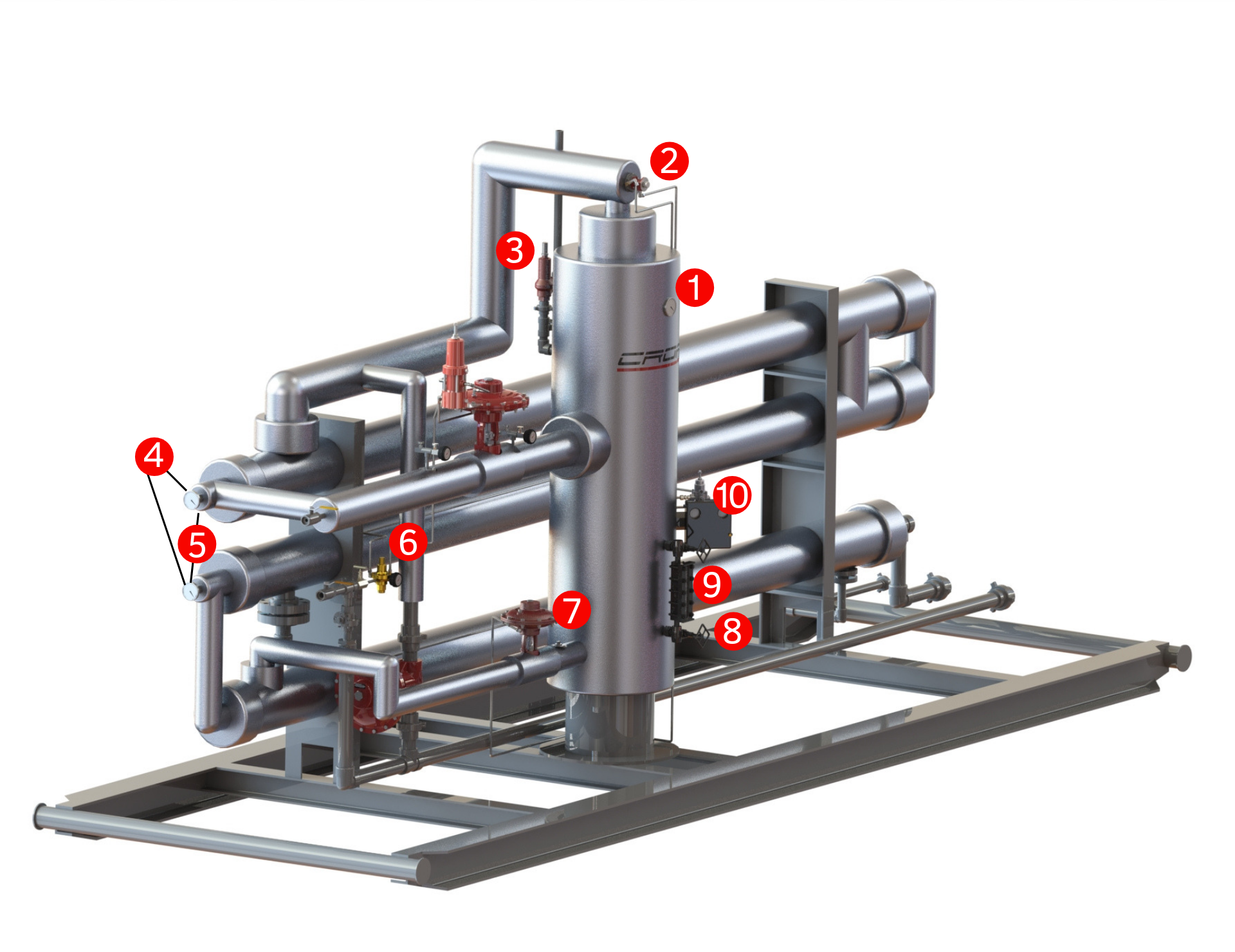

What parts go to a Joule Thomson Plant (JTS)?

It is recommended that the JTS be serviced on a 30-day schedule to ensure the system is running properly, as well as the parts. A JT plant relies heavily on its parts to achieve a pressure drop and as with any system, there are parts that can wear down over time.

1.Pressure Gauges – Pressure gauges are designed to show process pressure.

2.Temperature Controllers – Thermostats are used to control temperatures. If the process temperature goes under the set temperature, the thermostat will open supply to a bypass valve until a warmer set temperature is reached.

3.Pressure Safety Valves – A pressure safety valve is set to the unit’s maximum operating pressure to ensure safety. If the pressure exceeds that value, the valve will open, keeping the pressure within the safety limits.

4.Temperature Gauges – Temperature gauges are designed to show process temperature.

5.Thermowells – Thermowells are designed to block the process fluid and to be a connection port for temperature gauges.

6.Pressure Regulators – Pressure regulators regulate the pressure to levels that are suitable for instrumentation.

7.Dump Valves – Dump Valves keep the system's water and fluids at manageable levels by opening and releasing fluids when specified levels are reached.

8.Gauge Valve Sets – These valves are used when replacing a broken sight glass to isolate process fluid.

9.Sight Glass – A sight glass is a transparent tube that allows you to see the process fluid level inside a vessel.

10.Liquid Level Controllers – Liquid level controllers keep the system's water and fluids at manageable levels by triggering dumps to release fluids when they reach specified levels.

Want to look at all the JT system parts Croftsupply.com has to offer? Click here.

Want to purchase used or surplus equipment? Click here for SurplusEnergyEquipment.com

Want to lease or purchase new or re-certified JTS equipment? Click here.